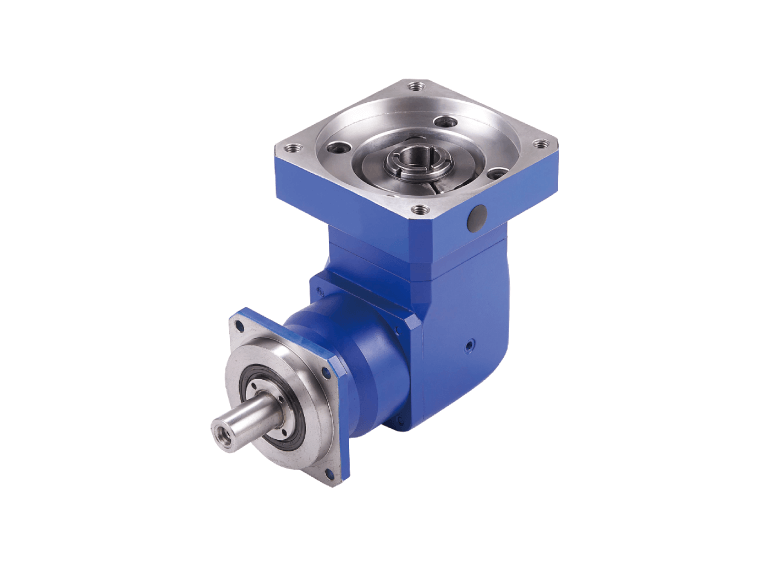

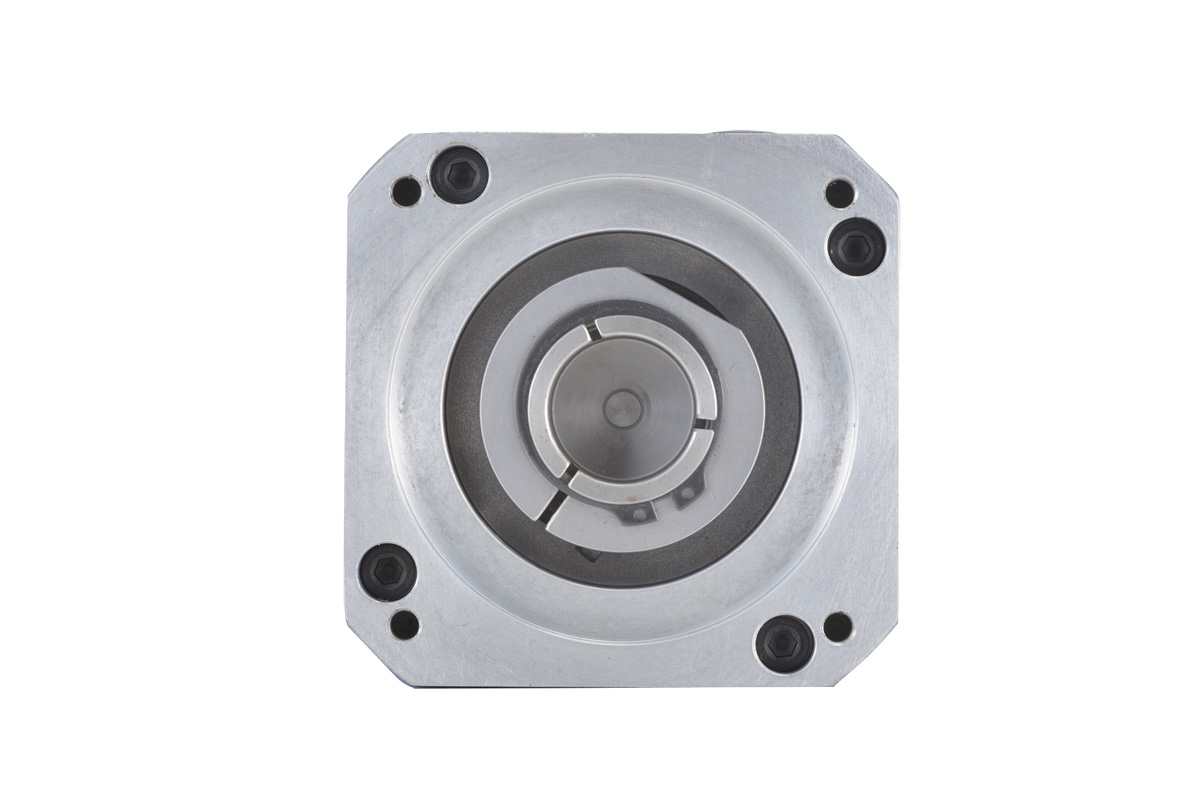

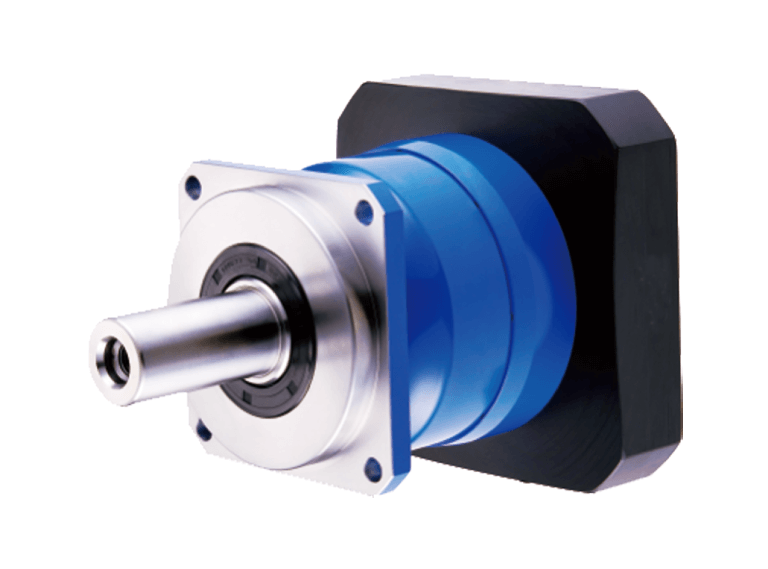

Hệ số backlash thấp

Bánh răng được kiểm soát chất lượng

Stage one backlash: ≤ 2 – 6 arcmins

Stage two backlash: ≤ 4 – 8 arcmins

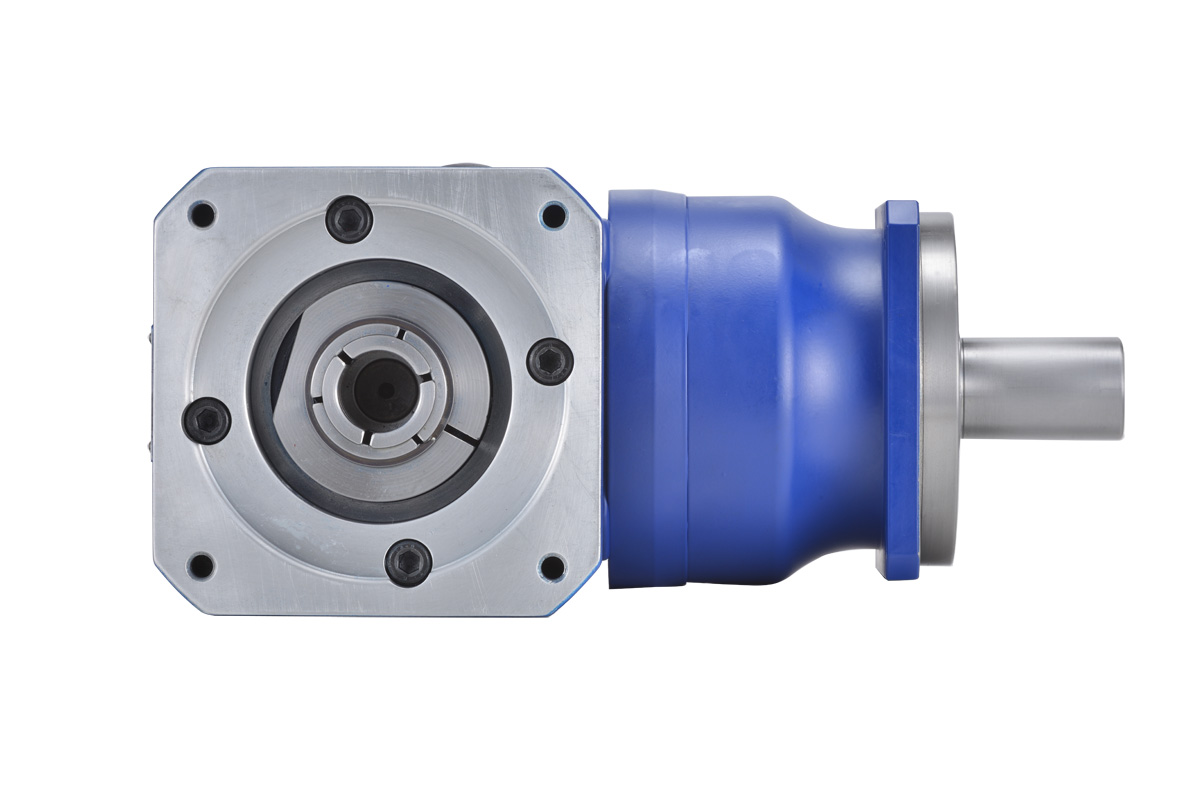

Hiệu quả cao

Stage one: ≤ 97% Stage two: ≤ 94%

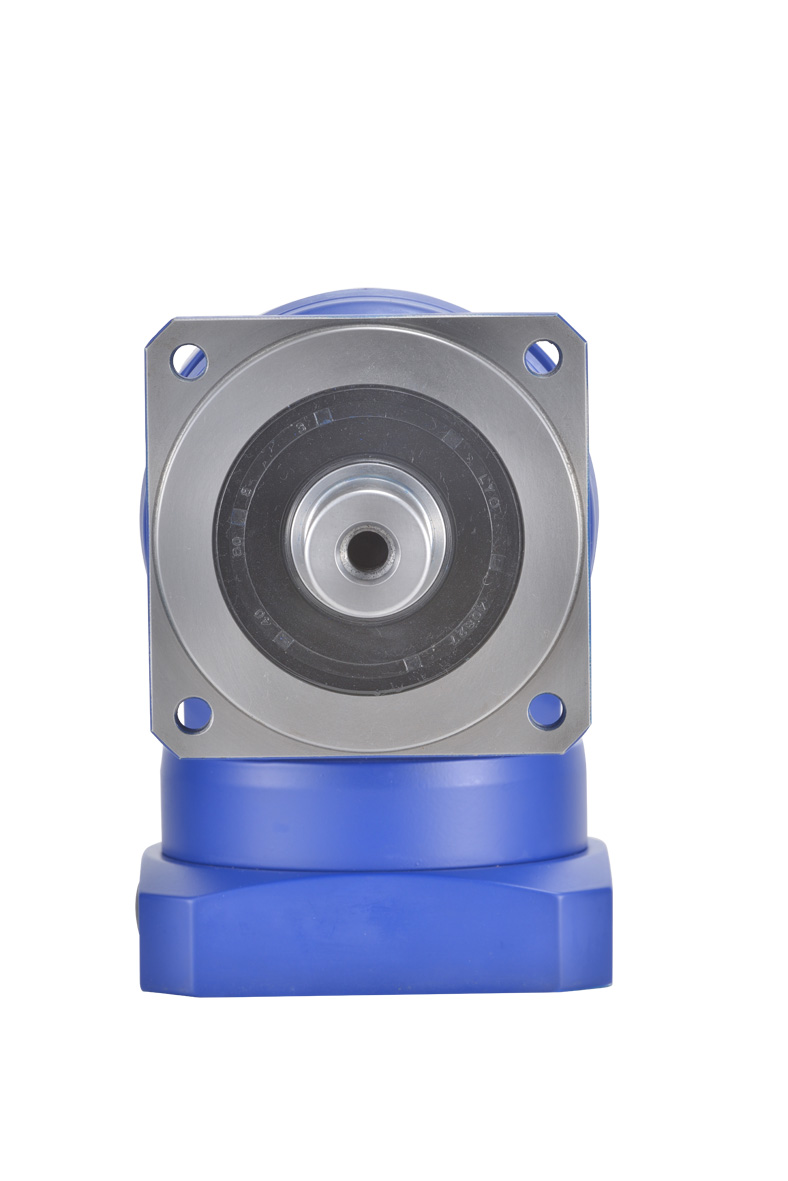

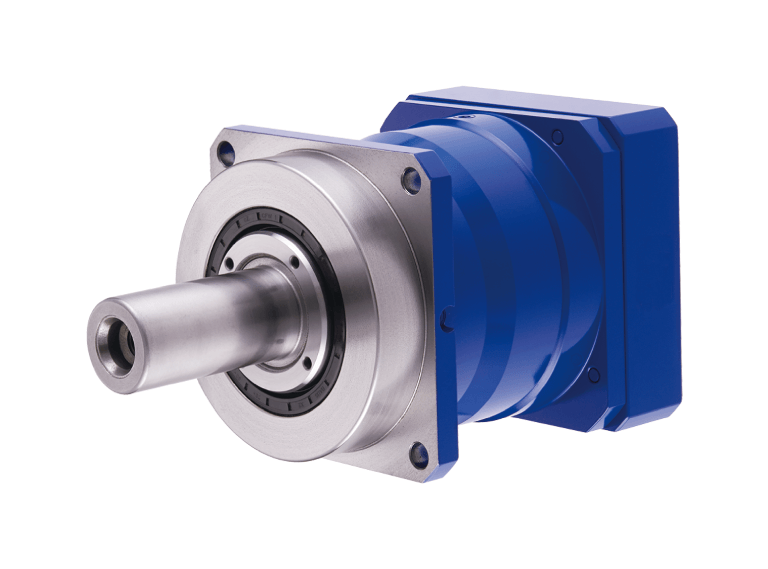

Trọng lượng nhỏ

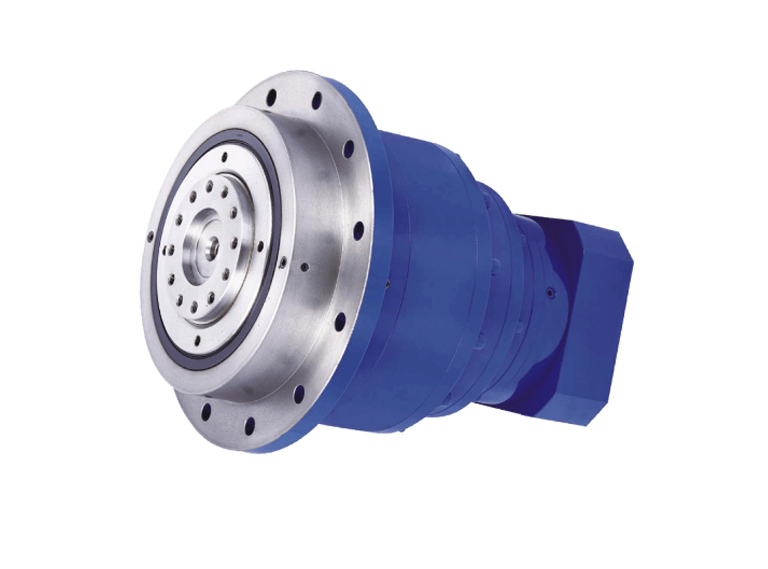

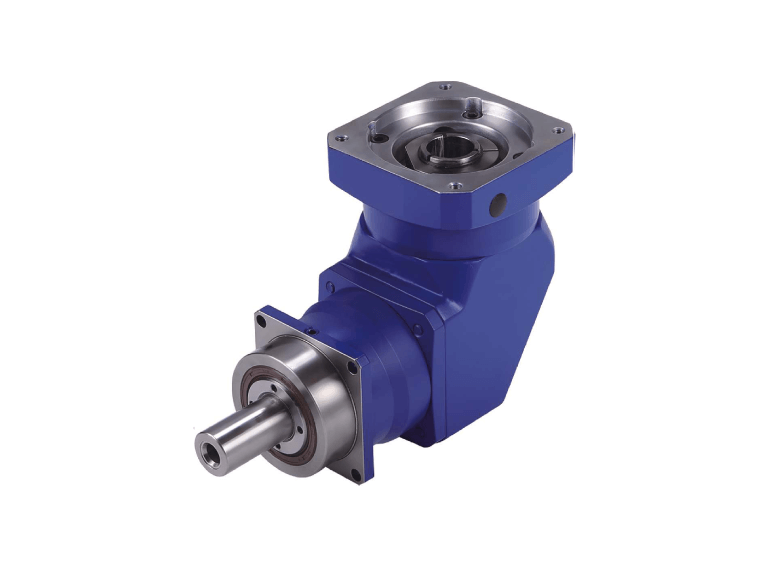

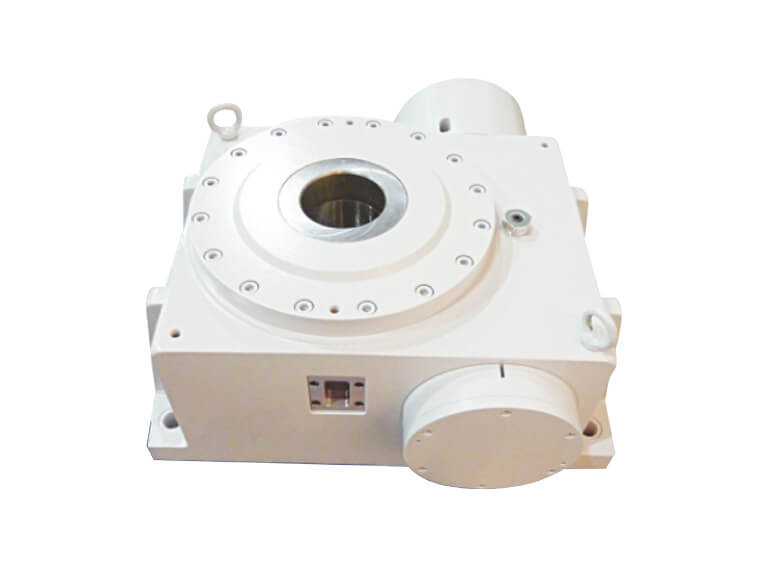

Hệ thống bánh răng hành tinh được thiết kế chính xác, nhỏ gọn, tiết kiệm không gian.

Dễ dàng lắp đặt, tiết kiệm không gian, giảm trọng lượng

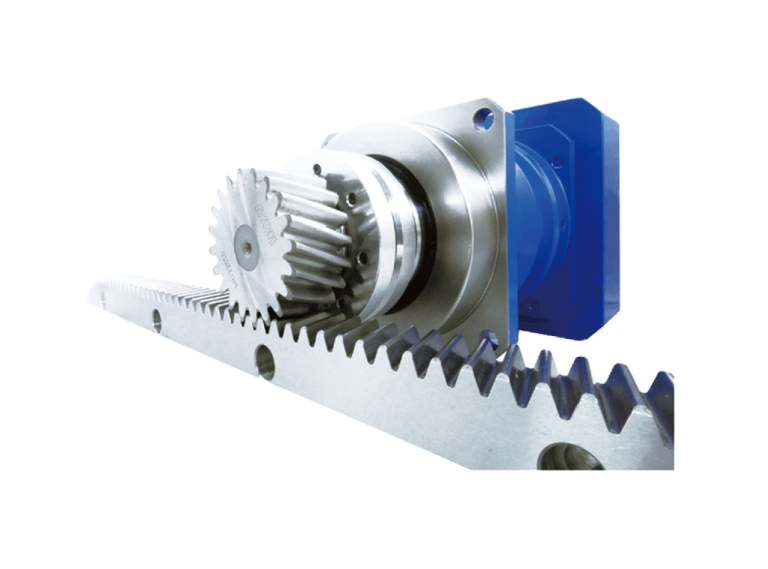

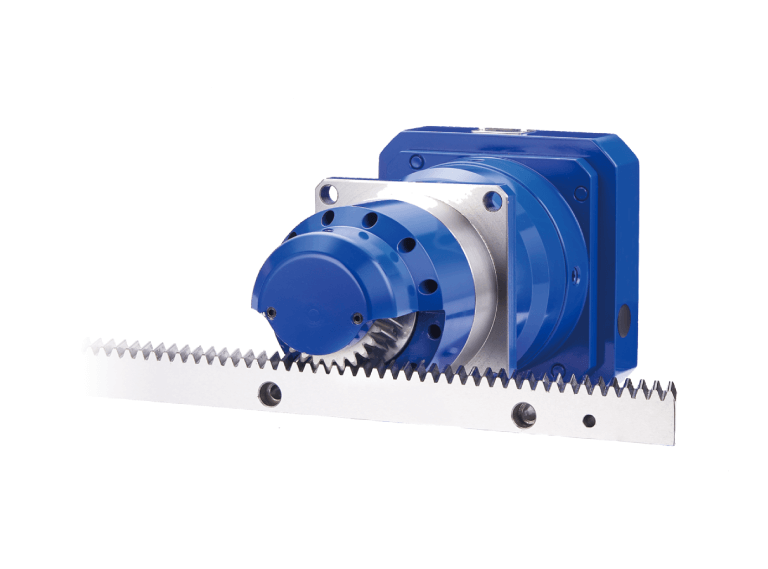

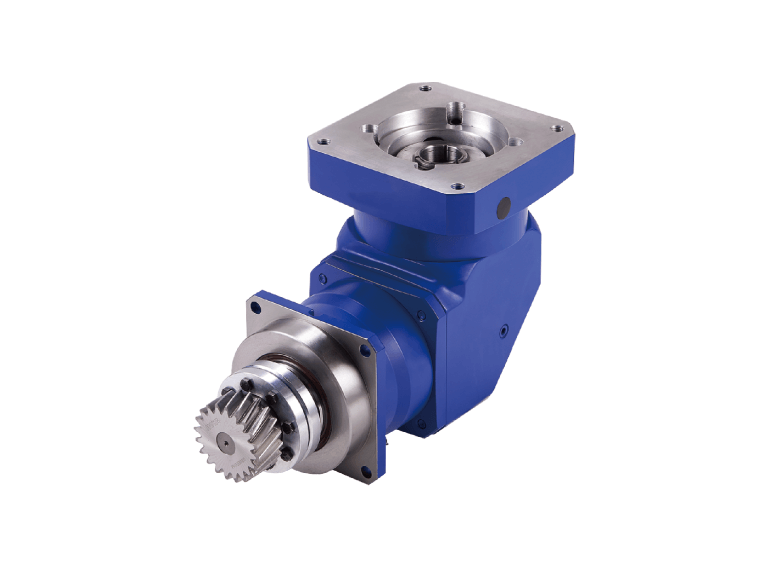

Bánh răng và trục đầu ra của hộp số được kết nối bằng khớp nối có độ cứng cao

Tuôi thọ dài

Thiết kế riêng biệt

Sử dụng bạc đạn côn chất lượng cao

Dầu tổng hợp được lựa chọn tốt nhất

Seal được nhập từ Đức

Phạm vi sử dụng của hộp số

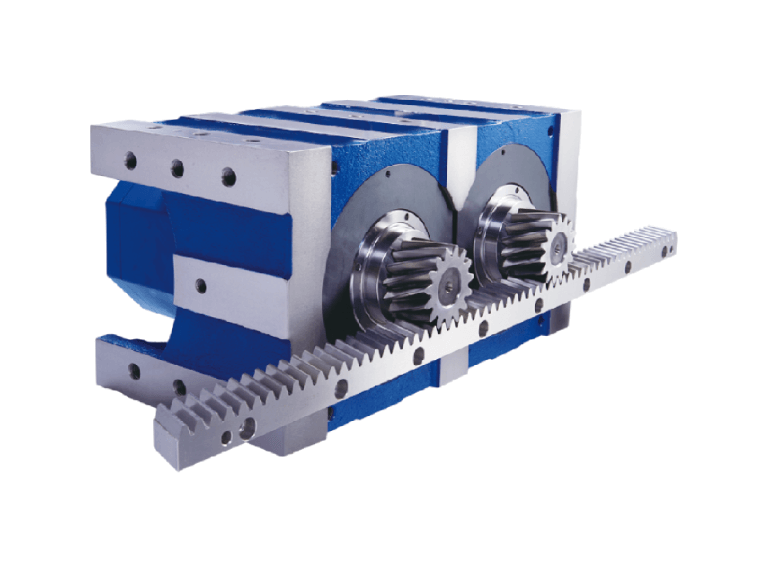

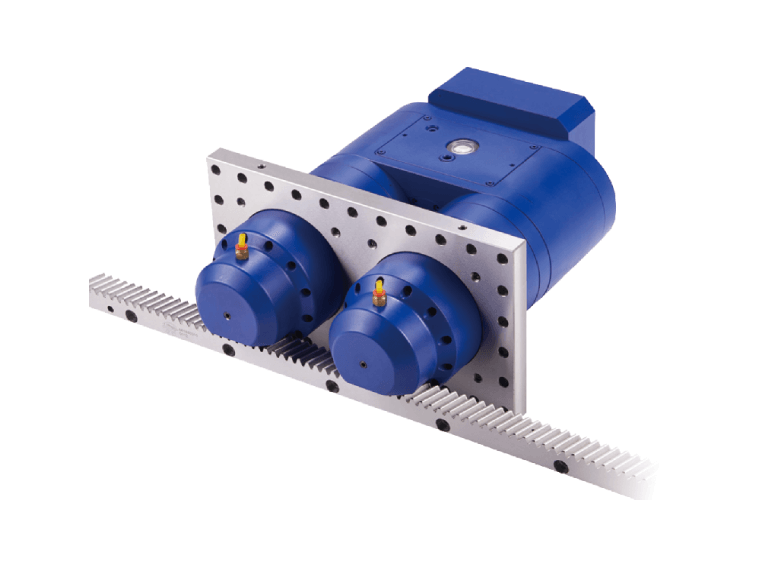

Máy công cụ:

Máy phay giàn CNC / Máy mài giàn CNC

Máy khoan, gia công lổ CNC

Tự động hóa trong nhà máy:

Máy móc thiết bị dẫn hướng

Thiết bị y tế

Hệ thống lưu trữ và trích xuất tự động

Máy móc có tác dụng đặc biệt:

Máy đóng gói, máy in, máy dệt

Máy chế biến gỗ, máy thổi khuôn, máy khắc

Máy cắt laser, máy hàn laser

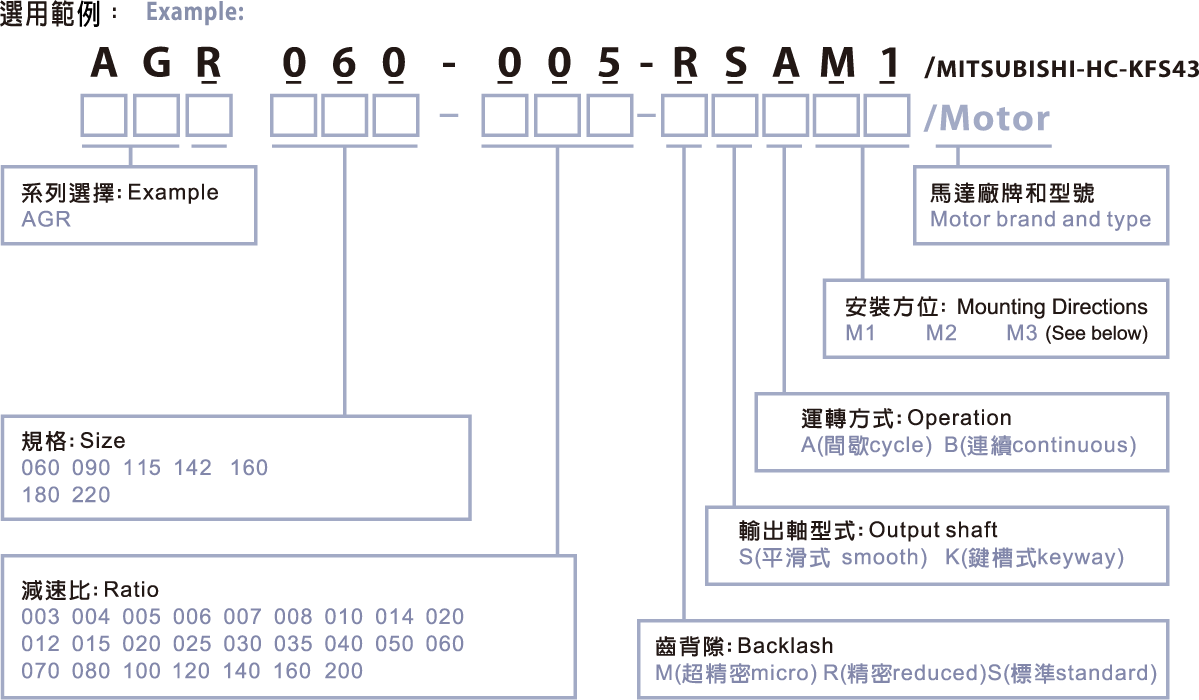

AGR Technical Data (1-Stage)

| Size | i | AGR060 | AGR090 | AGR115 | AGR140 | AGR160 | AGR180 | AGR220 | |

|---|---|---|---|---|---|---|---|---|---|

|

Output Torque (1) T2B |

Nm | 3 | 35 | 113 | 222 | 440 | 770 | 1165 | 1960 |

| 4 | 55 | 130 | 300 | 560 | 880 | 1450 | 2400 | ||

| 5 | 55 | 130 | 278 | 560 | 880 | 1450 | 2400 | ||

| 6 | 45 | 115 | 267 | 480 | 800 | 1220 | 2020 | ||

| 7 | 40 | 110 | 240 | 425 | 760 | 1085 | 1800 | ||

| 8 | 38 | 103 | 222 | 410 | 700 | 1045 | 1740 | ||

| 10 | 35 | 90 | 210 | 350 | 520 | 1000 | 1635 | ||

| 14 | 40 | 110 | 222 | 410 | 700 | 1045 | 1740 | ||

| 20 | 35 | 90 | 210 | 350 | 520 | 1000 | 1635 | ||

|

Emergency Stop Torque(2) T2Not |

Nm | 3 ~ 20 | 2.5 Times Output Torque | ||||||

|

Nominal Input speed n1N |

rpm | 3 ~ 20 | 4000 | 3000 | 3000 | 2000 | 2000 | 1500 | 1500 |

|

Max. Input speed n1Max |

rpm | 3 ~ 20 | 6000 | 5000 | 4500 | 3500 | 3000 | 2500 | 2000 |

|

Radial Load(3) Frmax |

N | 3 ~ 20 | 1000 | 3200 | 5800 | 7000 | 9400 | 12000 | 20000 |

|

Axical Load(3) Famax |

N | 3 ~ 20 | 500 | 1600 | 2900 | 3500 | 4700 | 6000 | 10000 |

| Micro Backlash | arcmin | 3 ~ 20 | - | ≦ 2 | ≦ 2 | ≦ 2 | ≦ 2 | ≦ 2 | ≦ 2 |

| Reduced Backlash | arcmin | 3 ~ 20 | ≦ 4 | ≦ 4 | ≦ 4 | ≦ 4 | ≦ 4 | ≦ 4 | ≦ 4 |

| Standard Backlash | arcmin | 3 ~ 20 | ≦ 6 | ≦ 6 | ≦ 6 | ≦ 6 | ≦ 6 | ≦ 6 | ≦ 6 |

| Torsional Rigidity | Nm/arcmin | 3 ~ 20 | 5 | 10 | 24 | 50 | 95 | 150 | 220 |

| Efficiency with Full Load | % | 3 ~ 20 | ≧ 97 | ||||||

| Service Life Lh2 | h | 3 ~ 20 | 20000 | ||||||

| Weight | kg | 3 ~ 20 | 4.5 | 7.5 | 15.5 | 32 | 47 | 72.5 | 113 |

| Noise Level(4) | dB | ≦ 63 | ≦ 65 | ≦ 68 | ≦ 70 | ≦ 70 | ≦ 71 | ≦ 73 | |

| Permissible Gear Reducer Temp | °C | -10°C ~ +90°C | |||||||

| Protection Class | IP 64 | ||||||||

| Lubrication | Synthetic oil viscosity ISO VG 220 | ||||||||

| Mass Moments of Inertia J1 | kg‧cm2 | i | AGR060 | AGR090 | AGR115 | AGR142 | AGR160 | AGR180 | AGR220 |

| 3 ~ 10 | 0.93 | 3.45 | 10.6 | 22.95 | 43.4 | 77.3 | 166.7 | ||

| 14 / 20 | 0.77 | 2.9 | 9.15 | 18.1 | 30.6 | 59.1 | 102.4 | ||

Note (1) The data can be applied to starting frequency less than 1000 times per hour. Please contact us if more.

Note (2) Operation can be up to 1000 times in product life.

Note (3) It acts on in the output shaft center at output speed 100 rpm.

Note (4) Noise inspection of ratio-5 reducers measure at input speed 3000 rpm, in 1-meter distance, and with free-load operation.

Continuous operation will cause half of reducer life decreased.

If any customized ratios are not available from above, please contact us.

AGR Technical Data (2-Stage)

| Size | i | AGR060 | AGR090 | AGR115 | AGR140 | AGR160 | AGR180 | AGR220 | |

|---|---|---|---|---|---|---|---|---|---|

|

Output Torque (1) T2B |

Nm | 12 / 15 | 35 | 113 | 222 | 440 | 770 | 1165 | 1960 |

| 20 / 25 | 55 | 130 | 300 | 560 | 880 | 1450 | 2400 | ||

| 30 | 45 | 113 | 222 | 440 | 800 | 1165 | 1960 | ||

| 35 / 40 / 50 | 55 | 130 | 300 | 560 | 880 | 1450 | 2400 | ||

| 60 / 120 | 45 | 115 | 278 | 480 | 800 | 1220 | 2020 | ||

| 70 / 140 | 40 | 110 | 267 | 425 | 760 | 1085 | 1800 | ||

| 80 / 160 | 38 | 103 | 240 | 410 | 700 | 1045 | 1740 | ||

| 100 / 200 | 35 | 90 | 210 | 350 | 520 | 1000 | 1635 | ||

|

Emergency Stop Torque(2) T2Not |

Nm | 12 ~ 200 | 2.5Times Output Torque | ||||||

|

Nominal Input speed n1N |

rpm | 12 ~ 200 | 4000 | 3000 | 3000 | 2000 | 2000 | 2000 | 1500 |

|

Max. Input speed n1Max |

rpm | 12 ~ 200 | 6000 | 5000 | 4500 | 3500 | 3000 | 3500 | 2500 |

|

Radial Load(3) Frmax |

N | 12 ~ 200 | 1000 | 3200 | 5800 | 7000 | 9400 | 12000 | 20000 |

|

Axical Load(3) Famax |

N | 12 ~ 200 | 500 | 1600 | 2900 | 3500 | 4700 | 6000 | 10000 |

| Micro Backlash | arcmin | 12 ~ 200 | - | ≦ 4 | ≦ 4 | ≦ 4 | ≦ 4 | ≦ 4 | ≦ 4 |

| Reduced Backlash | arcmin | 12 ~ 200 | ≦ 6 | ≦ 6 | ≦ 6 | ≦ 6 | ≦ 6 | ≦ 6 | ≦ 6 |

| Standard Backlash | arcmin | 12 ~ 200 | ≦ 8 | ≦ 8 | ≦ 8 | ≦ 8 | ≦ 8 | ≦ 8 | ≦ 8 |

| Torsional Rigidity | Nm/arcmin | 12 ~ 200 | 5 | 10 | 24 | 50 | 95 | 150 | 220 |

| Efficiency with Full Load | % | 12 ~ 200 | ≧ 97 | ||||||

| Service Life Lh2 | h | 12 ~ 200 | 20000 | ||||||

| Weight | kg | 12 ~ 200 | 4.0 | 7.2 | 13.5 | 27.5 | 36.5 | 51.5 | 84.5 |

| Noise Level(4) | dB | ≦ 63 | ≦ 65 | ≦ 68 | ≦ 68 | ≦ 70 | ≦ 71 | ≦ 73 | |

| Permissible Gear Reducer Temp | °C | -10°C ~ +90°C | |||||||

| Protection Class | IP 64 | ||||||||

| Lubrication | Synthetic oil viscosity ISO VG 220 | ||||||||

| Mass Moments of Inertia | kg‧cm2 | i | AGR060 | AGR090 | AGR115 | AGR142 | AGR160 | AGR180 | AGR220 |

| 12 ~ 100 | 0.93 | 3.45 | 10.6 | 22.95 | 22.95 | 22.95 | 77.3 | ||

| 120 / 200 | 0.77 | 2.87 | 9.15 | 18.1 | 18.1 | 18.1 | 59.1 | ||

Note (1) The data can be applied to starting frequency less than 1000 times per hour. Please contact us if more.

Note (2) Operation can be up to 1000 times in product life.

Note (3) It acts on in the output shaft center at output speed 100 rpm.

Note (4) Noise inspection of ratio-5 reducers measure at input speed 3000 rpm, in 1-meter distance, and with free-load operation.

Continuous operation will cause half of reducer life decreased.

If any customized ratios are not available from above, please contact us.

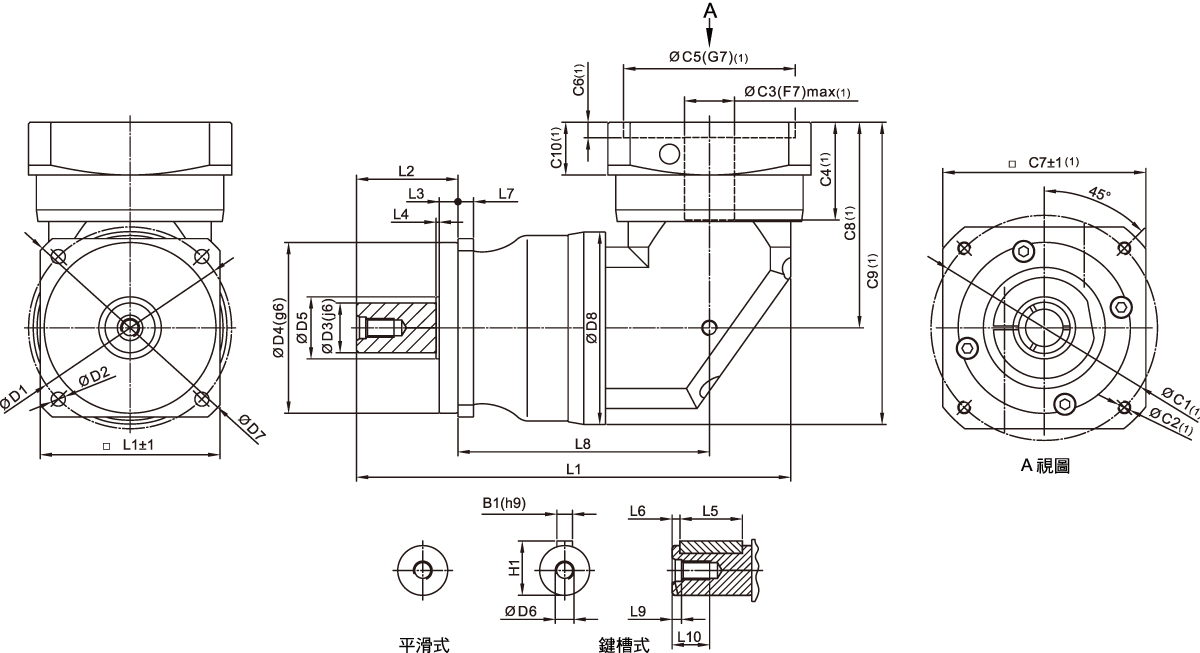

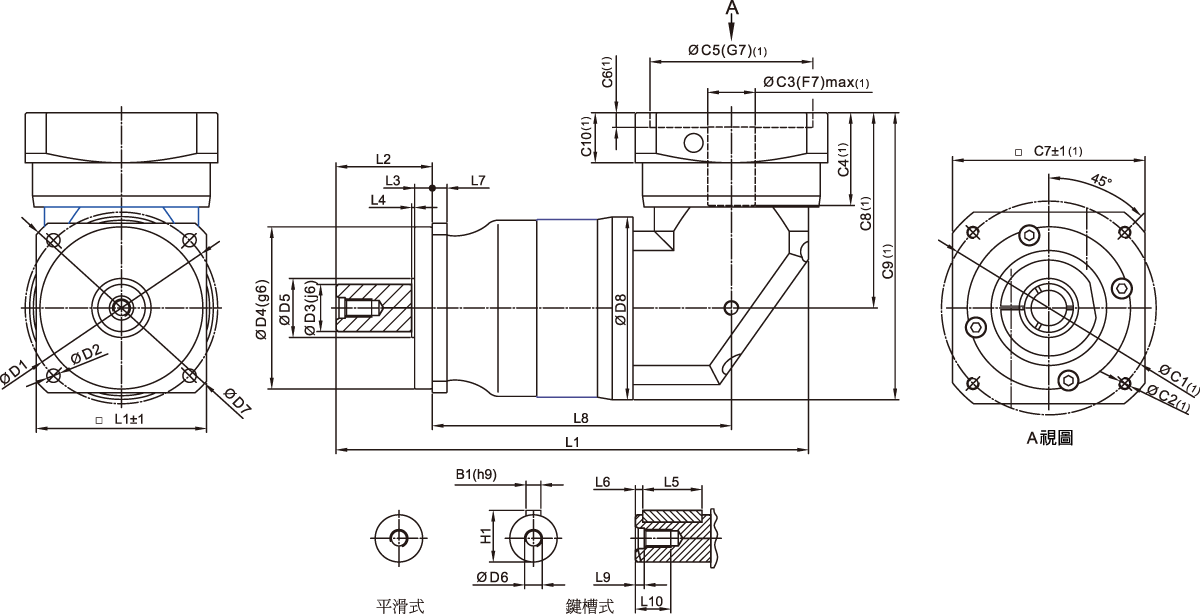

AGR Dimensions (1-Stage 3 ~ 20 Ratio)[mm]

| Size | AGR060 | AGR090 | AGR115 | AGR142 | AGR160 | AGR180 | AGR220 |

|---|---|---|---|---|---|---|---|

| D1 | 70 | 100 | 130 | 165 | 190 | 215 | 250 |

| D2 | 5.5 | 6.6 | 9 | 11 | 13 | 13 | 17 |

| D3 (j6) | 16 | 22 | 32 | 40 | 50 | 55 | 75 |

| D4 (g6) | 50 | 80 | 110 | 130 | 145 | 160 | 180 |

| D5 | 20 | 35 | 40 | 50 | 60 | 65 | 85 |

| D6 | M5*P0.8 | M8*P1.25 | M12*P1.75 | M16*P2 | M16*P2 | M20*P2.5 | M20*P2.5 |

| D7 | 80 | 116 | 152 | 185 | 215 | 240 | 292 |

| L1 | 172.5 | 213 | 280 | 355 | 395 | 436 | 519.5 |

| L2 | 37 | 48 | 65 | 97 | 97 | 105 | 138 |

| L3 | 7 | 10 | 12 | 15 | 15 | 20 | 30 |

| L4 | 1.5 | 1.5 | 2 | 3 | 3 | 3 | 3 |

| L5 | 25 | 32 | 40 | 63 | 70 | 70 | 90 |

| L6 | 2 | 3 | 5 | 5 | 5 | 6 | 7 |

| L7 | 6 | 8 | 10 | 12 | 13.5 | 15 | 20 |

| L8 | 102 | 123.5 | 161 | 189 | 216 | 234 | 270.5 |

| L9 | 4 | 4 | 6 | 7.5 | 10 | 12 | 12 |

| L10 | 12.5 | 19 | 28 | 36 | 36 | 42 | 42 |

| C1 (1) | 70 | 90 | 145 | 165 | 200 | 215 | 215 |

| C2 (1) | M5*P0.8 | M6*P1 | M8*P1.25 | M10*P1.5 | M12*P1.75 | M12*P1.75 | M12*P1.75 |

| C3 (F7) max.(1) | < 14 | < 24 | < 32 | < 38 | < 42 | < 48 | < 55 |

| C4 (1) | 36 | 49.7 | 60 | 72.2 | 75.2 | 86 | 93.5 |

| C5 (G7) (1) | 50 | 70 | 110 | 130 | 114.3 | 180 | 180 |

| C6 (1) | 6 | 5 | 6 | 8 | 7 | 8 | 8 |

| C7 (1) | 76.2 | 95 | 118 | 153.5 | 176 | 190 | 190 |

| C8 (1) | 89 | 107.5 | 129.5 | 185.5 | 176.5 | 201 | 226 |

| C9 (1) | 122.5 | 157.5 | 191.4 | 235.5 | 265 | 301 | 342 |

| C10 (1) | 24 | 28 | 31 | 35 | 36 | 42 | 47 |

| B1 (h9) | 5 | 6 | 10 | 12 | 14 | 16 | 20 |

| H1 | 18 | 24.5 | 35 | 43 | 53.5 | 59 | 79.5 |

(1)The dimensions from C1 to C10 may vary with different servo motor collocation.

※We persistently research in and develop our products, and we have made every effort to maintain the specification data above correct. If there is any discrepancy between the data and real dimensions, please refer to products or may contact us for updated data.

AGR Dimensions (2-Stage 12 ~ 200 Ratio)[mm]

| Size | AGR060 | AGR090 | AGR115 | AGR142 | AGR160 | AGR180 | AGR220 |

|---|---|---|---|---|---|---|---|

| D1 | 70 | 100 | 130 | 165 | 190 | 215 | 250 |

| D2 | 5.5 | 6.6 | 9 | 11 | 13 | 13 | 17 |

| D3 (j6) | 16 | 22 | 32 | 40 | 50 | 55 | 75 |

| D4 (g6) | 50 | 80 | 110 | 130 | 145 | 160 | 180 |

| D5 | 20 | 35 | 40 | 50 | 60 | 65 | 85 |

| D6 | M5*P0.8 | M8*P1.25 | M12*P1.75 | M16*P2 | M16*P2 | M20*P2.5 | M20*P2.5 |

| D7 | 80 | 116 | 152 | 185 | 215 | 240 | 292 |

| L1 | 195.5 | 245 | 321 | 402.5 | 423 | 447 | 542.5 |

| L2 | 37 | 48 | 65 | 97 | 97 | 105 | 138 |

| L3 | 7 | 10 | 12 | 15 | 15 | 20 | 30 |

| L4 | 1.5 | 1.5 | 2 | 3 | 3 | 3 | 3 |

| L5 | 25 | 32 | 40 | 63 | 70 | 70 | 90 |

| L6 | 2 | 3 | 5 | 5 | 5 | 6 | 7 |

| L7 | 6 | 8 | 10 | 12 | 13.5 | 15 | 20 |

| L8 | 125 | 155.5 | 202 | 236.5 | 257 | 273 | 307.5 |

| L9 | 4 | 4 | 6 | 7.5 | 10 | 12 | 12 |

| L10 | 12.5 | 19 | 28 | 36 | 36 | 42 | 42 |

| C1 (1) | 70 | 90 | 145 | 165 | 200 | 215 | 215 |

| C2 (1) | M5*P0.8 | M6*P1 | M8*P1.25 | M10*P1.5 | M12*P1.75 | M12*P1.75 | M12*P1.75 |

| C3 (F7) max. (1) | < 14 | < 24 | < 32 | < 38 | < 38 | < 38 | < 48 |

| C4 (1) | 36 | 49.7 | 60 | 72.2 | 72.2 | 72.2 | 86 |

| C5 (G7) (1) | 50 | 70 | 110 | 130 | 130 | 130 | 180 |

| C6 (1) | 6 | 5 | 6 | 8 | 8 | 8 | 8 |

| C7 (1) | 76.2 | 95 | 118 | 153.5 | 153.5 | 153.5 | 190 |

| C8 (1) | 89 | 107.5 | 129.5 | 158.5 | 158.5 | 158.5 | 201 |

| C9 (1) | 122.5 | 157.5 | 191.4 | 235.5 | 243.5 | 257.5 | 316 |

| C10 (1) | 24 | 28 | 31 | 35 | 35 | 35 | 42 |

| B1 (h9) | 5 | 6 | 10 | 12 | 14 | 16 | 20 |

| H1 | 18 | 24.5 | 35 | 43 | 53.5 | 59 | 79.5 |

(1)The dimensions from C1 to C10 may vary with different servo motor collocation.

※We persistently research in and develop our products, and we have made every effort to maintain the specification data above correct. If there is any discrepancy between the data and real dimensions, please refer to products or may contact us for updated data.

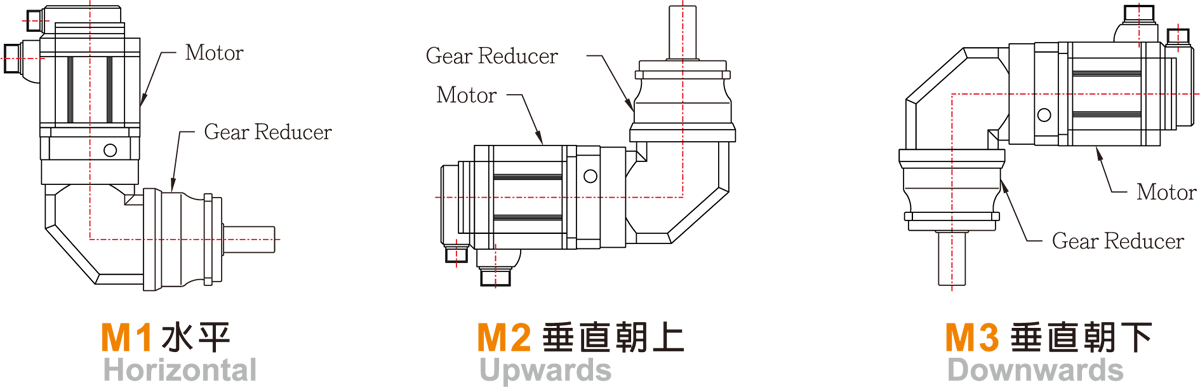

Directions:

Implementation:

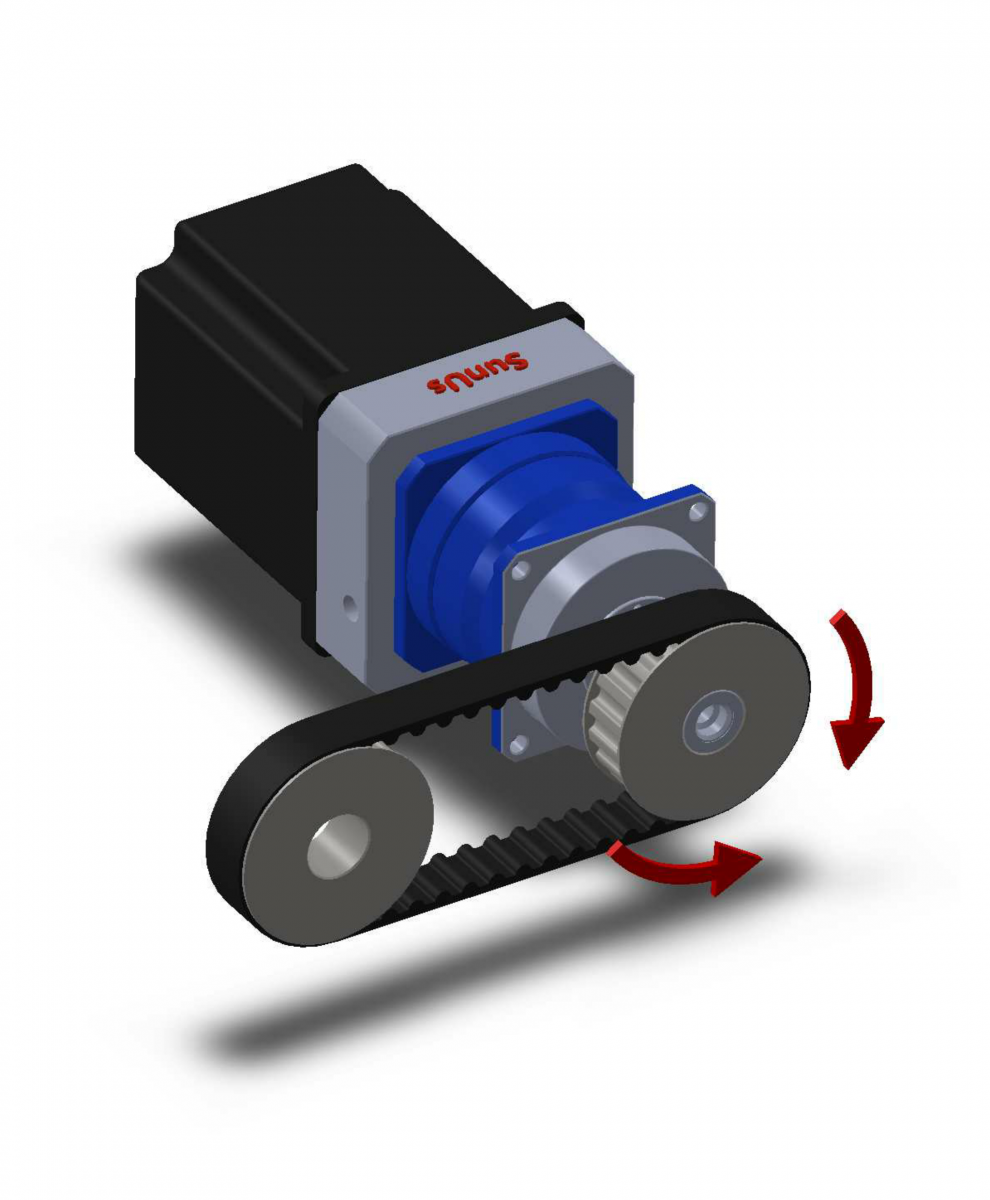

Pulley

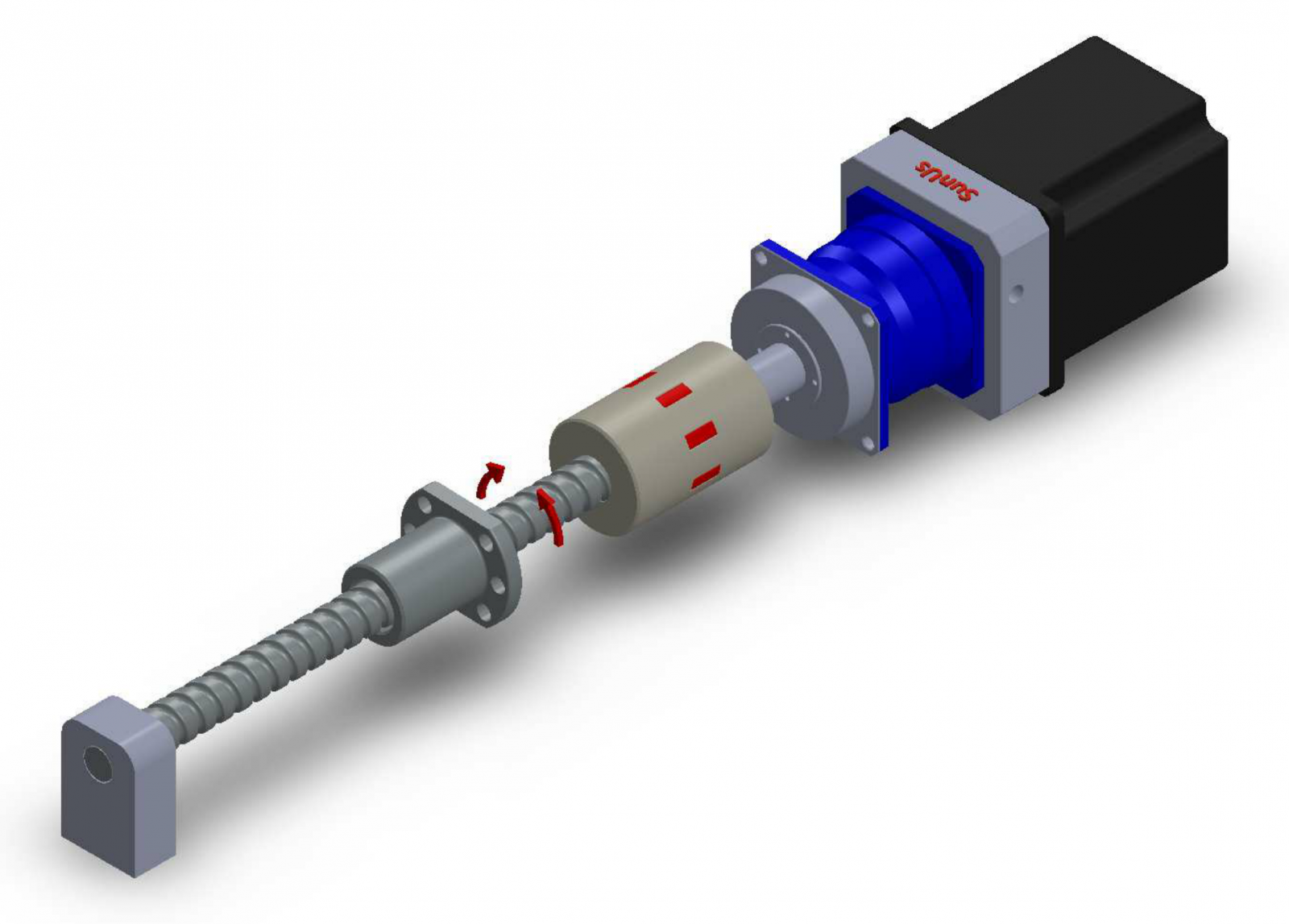

Ballscrew

Gọi điện

Gọi điện ZALO

ZALO Chỉ đường

Chỉ đường